Was it just a fad that’s come and gone or is it here to stay?

Recently, I came across the news that Ducati Corse has named Roboze as its Technical Partner for the 2022 season, which just started. You probably don’t know – I didn’t – that Roboze is a 3D printing company the Italian motorsports division has been working with for over a year. It helps quickly craft components for motorcycles using super polymers and composite materials, both for prototyping and finished products. This got me thinking about where the state of 3D printing in the motorcycle industry is at this point. After all, it seemed all the rage a few years ago, but you don’t hear nearly as much about it lately.

Listen to the Motorious Podcast here.

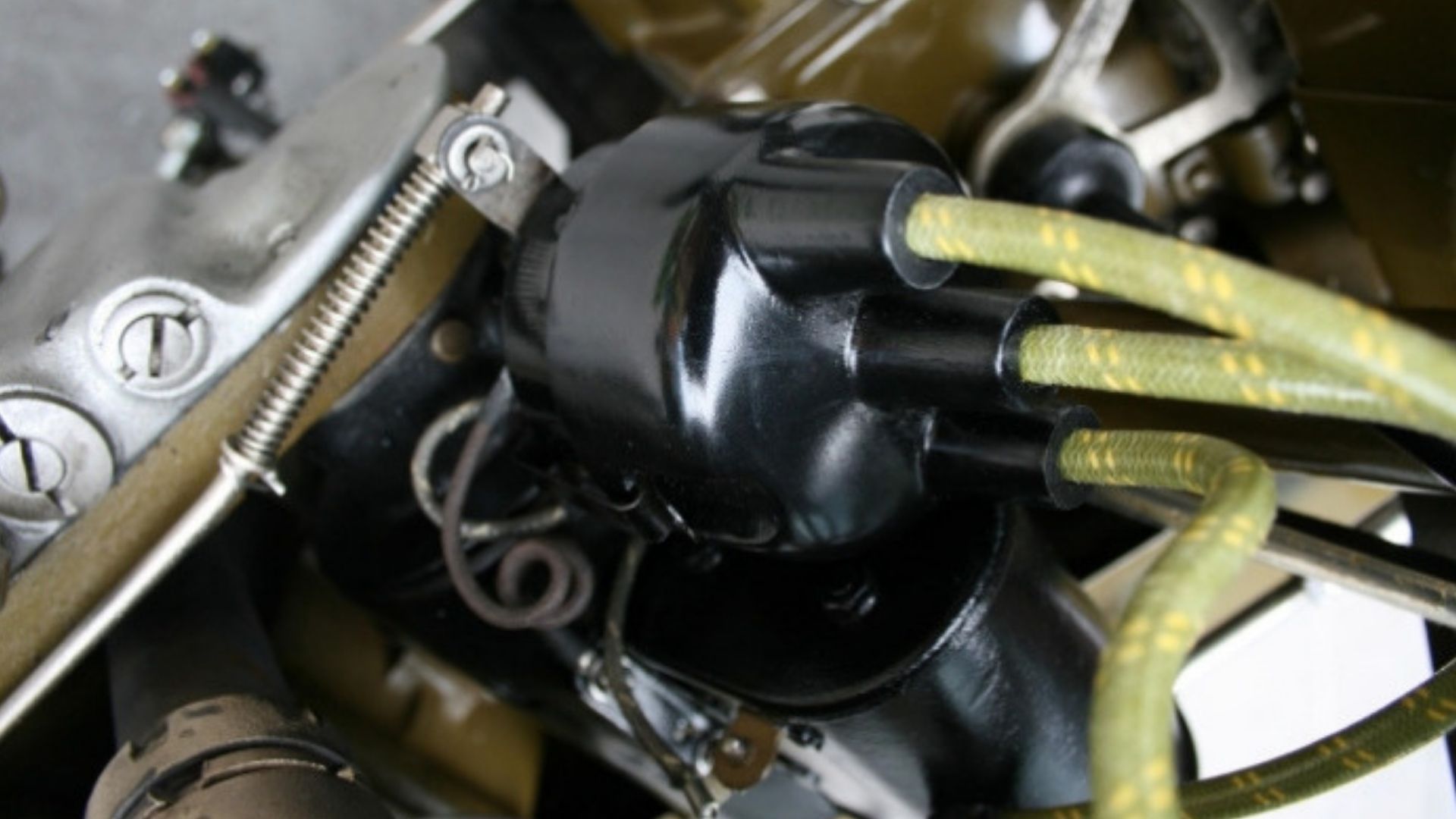

Visual First, a Dutch reverse engineering company, decided to use 3D printing to help restore a 1919 Harley-Davidson. As you might imagine, there’s no going down to the dealership to just pick up whatever parts the bike might be missing. One of the components which was broken and otherwise irreplaceable was the distributor cap. Despite the poor condition of the original part, the scanner was able to reconstruct how it should be.

Of course, you have to select what material to use for printing components. In the case of the 1919 Harley’s distributor cap, it was decided polyamide was the best solution. The polymer features repeating units linked by amide bonds, similar to what you find in proteins, making it both durable and strong. Once the part was printed, it was painted a glossy black to match the rest of the vintage motorcycle. The casual observer would never suspect a thing.

Back in 2018, TVNZ in New Zealand featured a story about a father and son who were beginning a 3D Printed motorcycle manufacturing venture. If you think that sounds crazy, you’re definitely not alone. After all, here we are four years later and 3D printing is still a fairly exotic thing. Sure, you see it done here and there, but it’s not like everyone has a 3D printer in their garage these days.

Staying on the bleeding edge of innovation is of course expensive. The son admitted to the reporter that they’re aiming at the luxury end of the market. Considering he estimates the bikes would cost over $250,000 NZD. However, he also said without 3D printing they would be a year or two behind in the development process from where they were. In other words, there are advantages and disadvantages to the tech, just like everything else.

Also back in 2018, BMW Motorrad got people talking when it announced a revolutionary 3D printing service for dealers. The BMW Motorrad iParts program was to be rolled out to 250 dealers worldwide. Each one was to get a large printer for use in the shop, allowing the printing of big, complex components. Even more interesting was the revealing of a small 3D printer which could be transported by motorcycle to remote customers for producing smaller, less complex components on the spot. What many didn’t realize until later was that the press release came out on April 1, so yes it was a joke. Still, some people got really excited about the possibilities, only to feel like their hopes had been weaponized against them. Did this hurt the image of 3D printing in the industry? Maybe some, even though I’d hope people would have a better sense of humor and less sensitive egos.

One of the most dramatic examples of 3D printing and motorcycles comes via the Nera. The all-electric bike was built almost entirely from printed components. Because the electric motor doesn’t generate as much heat as an internal combustion engine, additive manufacturing using polymers which don’t have the heat resistance of certain metals was possible. That in turn helps with lightweighting. Of course, the lithium-ion battery cells aren’t exactly light, so the goal is to balance that out if not achieve a net loss in the motorcycle’s weight. However, like so much of the 3D printing excitement in the motorcycle niche, the Nera premiered in 2018.

Of course, 3D printing motorcycle parts goes beyond just racing, concept builds, or expensive luxury models. It can help with customizing a bike in ways you might not have thought possible before. If you can find the right printing service, it’s possible to collaborate on creating something completely unique. And with the growing use of metals in additive manufacturing, you don’t have to stick just to plastic components. In other words, it’s still around even though 3D printing for motorcycles isn’t getting as much press coverage these days.